How could we design a product for 9 lives?

Mark Young is a product designer based in Gloucestershire. In this blog he talks us through his ideas for designing products with real longevity.

For most designers, designing something for 1 life is hard enough. So much to consider. Thinking about what your product will do at the end of its life is not instinctive. It’s a bit like planning a funeral at a baby’s birth: Not the first thing on your mind. Yet if you choose a material that will outlive its initial function by hundreds of years then you need to think further ahead.

I’ve been fascinated by 2 companies who are known as leaders in remanufacturing: CAT and Fujitsu. One makes earth moving equipment; the other photocopiers. What they both do is design certain components to be used in 4,5,6,7 machines over that component’s life.

Finding exactly how they do this is not easy so I got thinking about approaches to help us think ahead. What design tools could help us in this quest?

FUNCTIONAL CASCADING, FUNCTION SCHEDULING, 9 JOBS….

Not catchy names. But they do capture what I’m getting at: A way to plan future lives for the things we make.

I’m also aware that ‘Lives’ is not quite the way to describe this either, as a part only really has 1 life but may have various roles or jobs in its life. More accurate but I’m sticking with 9 Lives for now as I think the metaphor works to explain the concept. A cat turns 1 life into 9 by dodging potentially life-ending situations. Plus, I like cats.

HOW DOES IT WORK?

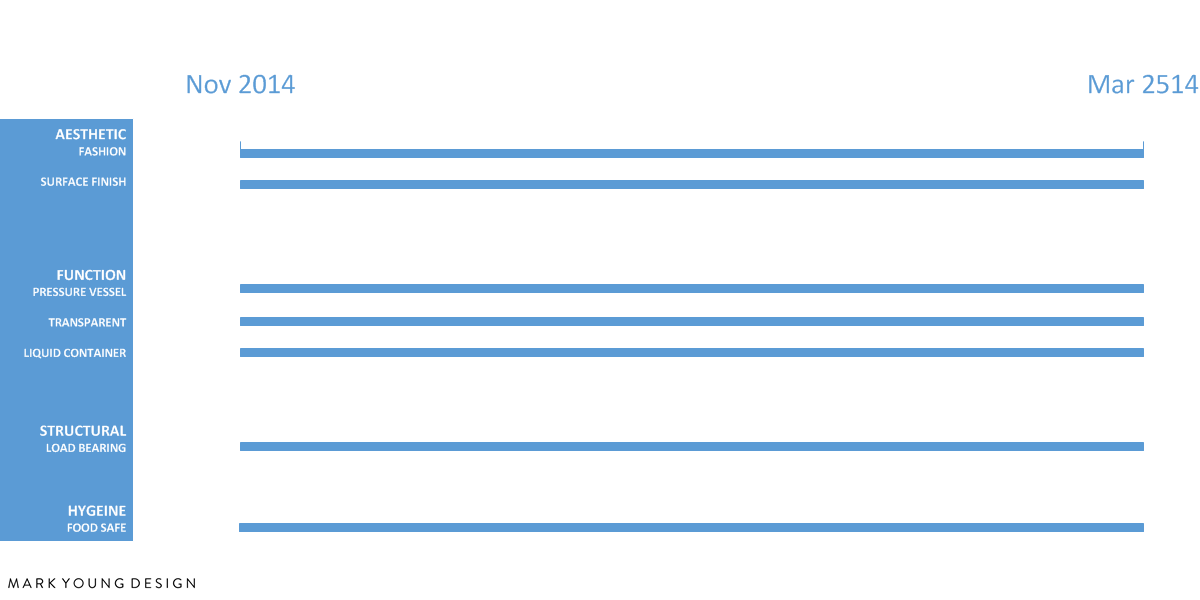

There are various attributes that a product or component has. Some are consciously designed in. Some are not. Here’s some examples:

AESTHETIC

Surface Finish

Fashion

FUNCTION

Pressure vessel

Sharpness

Wheel

Transparent

STRUCTURAL

Load Bearing

HYGIENE

Food

Medical

ELECTRONIC

Speed

Compatibility

Efficiency

How these attributes are maintained over time can dictate how many lives (or roles, or jobs) a thing can do. If we lay these out on a timeline, we can start to imagine how useful it could be in the future.

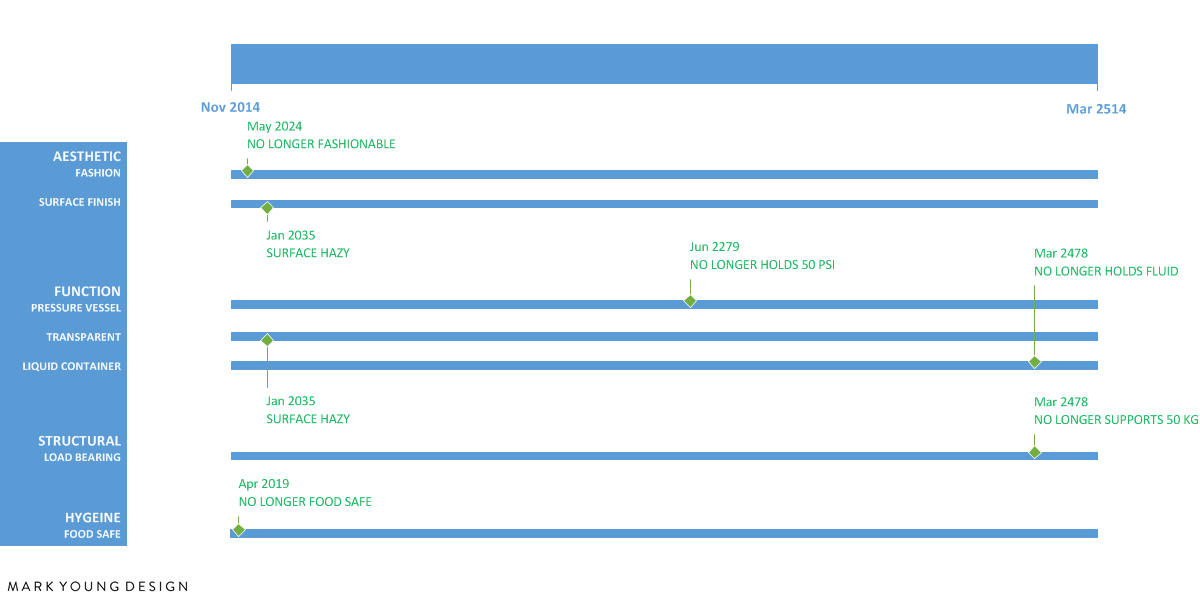

So with this framework, the next step is to predict how the product will perform over time. This is tricky. The thingamajig has left the factory and how it’s treated is out of the designer’s hands. But let’s be optimistic. What would be the best life or lives for our thing? If it was well cared for, what’s the best we could hope for?

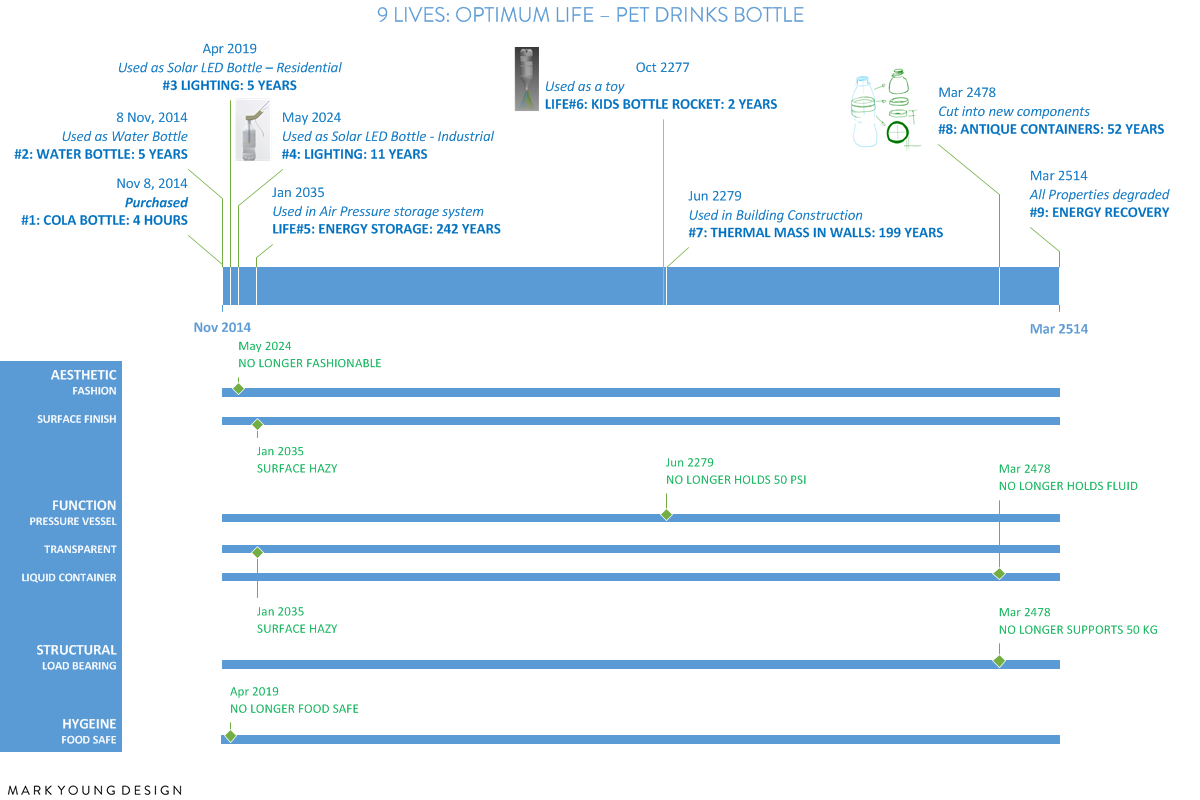

For an example I’m going to use the humble and magnificent PET drinks bottle. It’s made from a material that we are told could last 500 years. Having been invented only 60 years ago, nobody really knows yet. But again, let’s be optimistic. Let’s assume it could be useful until 2514. You buy it now, it’s still being used by your great-great-great-great-great-great-great-great-great-great-great-great-great-great-great-great-great-great-grandchildren

Why is the cheap, disposable, everyday thing magnificent? It holds a fluid that is essential to us. It’s transparent. It can hold very high pressures. It can be stacked, when pressurized, in huge quantities. It’s lightweight. It’s resilient. It can be made into beautiful forms. It’s made from a material that the biosphere can’t break down for hundreds of years. It’s amazing. And generally we drink the drink and throw it ‘away’ within a day. Or maybe hours.

At the other extreme, we could keep it useful for 500 years. That’s 182,500 days. This is before we even recycle or burn it for energy. But how?

Here’s my analysis of its maximum working life, based on these attributes.

I’ve made some assumptions here. Quite a few. I’d like to show how short the typical working life of a bottle is but on this timeline it’s just microscopic. Hopefully what’s abundantly clear is that there’s a lot more life, or lives, in this thing than we currently get out of it.

Plastics are very resilient but in terms of mechanical properties they will degrade over time. UV light is the main culprit. Knowing this, we could schedule different lives in advance. Its pristine appearance will gradually degrade. We’ll probably be bored of the appearance way before that. That’s OK – we’ll just hide it away! Then finally, after a full life, we cremate it, releasing its embodied energy (from our fossilized ancestors millions of years ago) 500 years after it was taken from under the ground. 500 years of life, instead of a week or two.

A more fitting end.

So based on this analysis I’ve thought about specific lives and when they should be scheduled. To take maximum advantage of the properties that degrade the quickest (like transparency) I’ve scheduled those particular lives earlier on.

So here we’ve managed to think of 9 lives (a coincidence, honestly….) for our PET drinks bottle. There could be more. We have at least a plan for what to do with this bottle after the drink has been drunk. By doing this at the design stage it gives us a way to reconsider our design beyond the 1st life:

For 137 years as a pressure vessel the thread and seal area is critical. So a well-engineered thread form keeps it useful for longer. Increasing the wall thickness by 0.2mm would keep it stronger for longer (something to consider when bottles are being ‘lightweighted’ to be ‘greener’) and reduce the chance of leaking.

Extra information marked on the bottle would also help future users: Date of manufacture lets us know the age; a material code, with extra details of fillers and additives will help those future users understand how it might break down; embodied energy tells future users how much energy they’ll get when it comes time to burn it.

I realise the biggest problem in this kind of planning is matching quantities. You might get through 365 PET bottles of drink in a year but you might need 1 solar LED bottle every 5 years. Using this approach though that kind of planning could become easier.

When it comes to non-biodegradable, “Technical Nutrients” like PET we need to design for a multitude of lives. Not just to grab attention on the shelf – that’s over in the blink of the eye – but for a full and useful life that takes advantage of the amazing properties of the materials we invent.

If you think this could be useful and have any feedback then please get in touch!