Voices from our circular network:

Todd Harrison, London-based freelance designer, discusses the rise of 3D printing and its potential contribution to a circular economy

Many of us live in a throwaway culture of convenience, strongly influenced by the consumption of short-lived items. There’s a disconnection between users and the products they use. Users often have no idea how their things are put together or made; they’re sealed up, with their inner workings hidden from view.

This may in part be because companies and manufacturers are often far from the users, both geographically and in spirit. It may too be because of high Intellectual Protection ratings for certain products, or for safety reasons in others.

Accessibility of 3D printing

However, if we can bring users closer to the factory, an object may become more valuable to them and, as well as increasing the users’ knowledge about the objects they use, may develop further self-reliance.

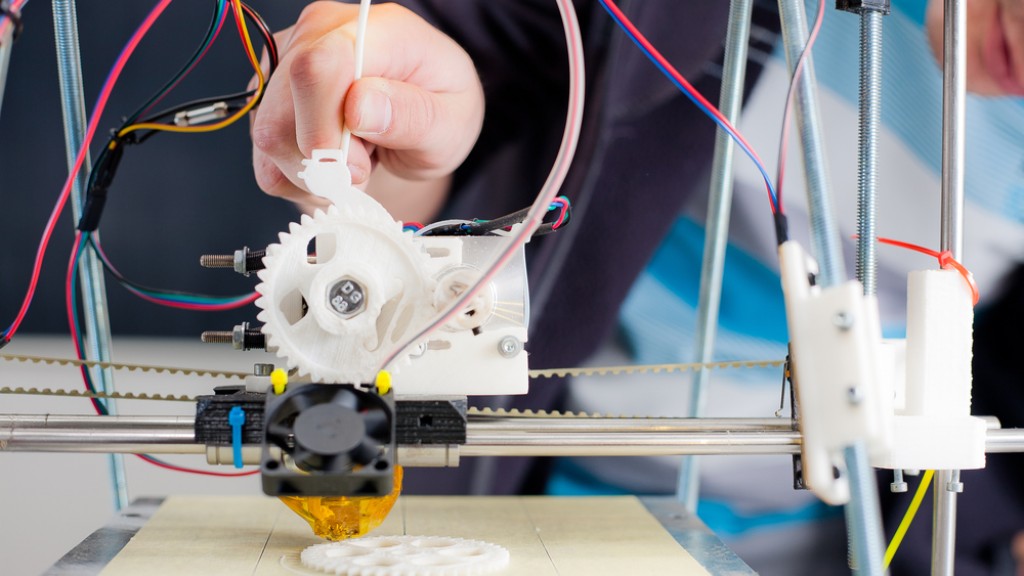

3D printers could enable this, and are expected to become as popular in the home in the next decade as traditional printers are today. 3D printing has come a long way from only four or five years ago when it was known as rapid prototyping. The technology is now being developed for a whole raft a materials and industries, even being employed print human organs.

This technology is already being brought closer to users with the emergence of 3D printing hubs that are springing up in cities around the world. Whilst these are predominantly being used for prototyping, it is a sign of things to come in terms of accessibility to manufacture.

Distributed manufacturing

3D printing can drastically reduce the complex network needed for the production of products and their many components, and therefore allow users more control over the production of the items they use.

A spanner was recently emailed to the International Space Station so it could be printed – something that would otherwise have been very expensive and energy consuming to receive.

In a similar way, platforms such as Open Desk: a service that allows designers to upload designs such as that of a table or chair, allows users that may be on the other side of the world to source a local manufacturer to make it instead – allowing designs to cover most of their journey digitally rather than in physical form, and bringing users closer to the factory.

Aiding repair and design for a circular economy

Creating products that can easily be disassembled for repair or separating into their separate components for recycling is important for closed loop design. Can we use technology like 3D printers to allow for a shift towards a culture of repair? Allowing us to rattle off a new kettle element if we need one, and save us accepting a kettle as broken and sending off to landfill – an all too common end for such a product and its valuable materials.

Social platform Fixperts is a social platform that connects designers with people in need of something fixing. The aim is to produce a quick, low-cost solution to prevent the object being seen as broken and being discarded. Platforms like Fixperts are encouraging a culture of repair, and with materials such as Sugru now available, repairing and maintaining are becoming easier; whether that be rejoining a snapped component, or reinforcing the component to prevent it snapping in the first place.

3D printers are a new tool for a culture of repair, and can bring users into the factory, encouraging conscious consumption and heighten users connections with their products. And, if used responsibly, reduce the processes required within the circular economy.